Abstract

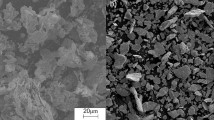

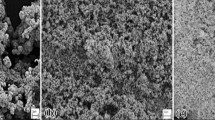

In this study, large micron-sized SiC particles were fragmented via ball-milling process in the presence of iron and nickel powders, separately, to fabricate composite powders of Fe–SiC and Ni–SiC. Continuous fracturing of brittle SiC powders leads to the formation of multi-modal-sized SiC powders with size of from 50 nm to slightly higher than 10 µm after 36-h ball milling. The milled powders were then incorporated into the semisolid melt of A356 aluminum alloy to ease the incorporation of fine SiC particles by using iron and nickel as their carrier agents. The final as-cast composites were then extruded at 500 °C with a reduction ratio of 9:1. Lower-sized composite powders with slight agglomeration are obtained for the 36-h milled Ni–SiC mixture compared to that of Fe–SiC powders, leading to incorporation of SiC particles into the melt with a lower size and suitable distribution for the Ni–SiC mixture. It is found that lower-sized composite particles could release the fine SiC particles into the melt more easily, while large agglomerated composite particles almost remain in its initial form, resulting in sites of stress concentration and low-strength aluminum matrix composites. Ultimate tensile strength (UTS) and yield strength (YS) values of 243 and 135 MPa, respectively, are obtained for the aluminum matrix composite in which nickel acts as the carrier of fine ceramic particles.

Similar content being viewed by others

References

Khosroshahi NB, Mousavian RT, Khosroshahi RA, Brabazon D. Mechanical properties of rolled A356 based composites reinforced by Cu-coated bimodal ceramic particles. Mater Des. 2015;83:678.

Soltani S, Khosroshahi RA, Mousavian RT, Jiang Z-Y, Boostani AF, Brabazon D. Stir casting process for manufacture of Al–SiC composites. Rare Met. 2015;. doi:10.1007/s12598-015-0565-7.

Mousavian RT, Damadi S, Khosroshahi RA, Brabazon D, Mohammadpour M. A comparison study of applying metallic coating on SiC particles for manufacturing of cast aluminum matrix composites. Int J Adv Manuf Technol. 2015;81:433.

Mousavian RT, Khosroshahi RA, Yazdani S, Brabazon D, Boostani A. Fabrication of aluminum matrix composites reinforced with nano-to micrometer-sized SiC particles. Mater Des. 2016;89:58.

Boostani AF, Yazdani S, Mousavian RT, Tahamtan S, Khosroshahi RA, Wei D, Brabazon D, Xu JZ, Zhang XM, Jiang ZY. Strengthening mechanisms of graphene sheets in aluminium matrix nanocomposites. Mater Des. 2015;88:983.

Boostani AF, Mousavian RT, Tahamtan S, Yazdani S, Khosroshahi RA, Wei D, Xu JZ, Gong D, Zhang XM, Jiang ZY. Graphene sheets encapsulating SiC nanoparticles: a roadmap towards enhancing tensile ductility of metal matrix composites. Mater Sci Eng A. 2015;648:92.

Vijayarangan S, Rajamanickam N, Sivananth V. Evaluation of metal matrix composite to replace spheroidal graphite iron for a critical component, steering knuckle. Mater Des. 2013;43:532.

Tiruvenkadam N, Thyla P, Senthilkumar M, Bharathiraja M, Murugesan A. Synthesis of new aluminum nano hybrid composite liner for energy saving in diesel engines. Energy Convers Manag. 2015;98:440.

Chandran P, Sirimuvva T, Nayan N, Shukla AK, Murty SVSN, Pramod SL, Sharma SC, Bakshi SR. Effect of carbon nanotube dispersion on mechanical properties of aluminum–silicon alloy matrix composites. J Mater Eng Perform. 2014;23(3):1028.

Mohammadpour M, Khosroshahi RA, Mousavian RT, Brabazon D. Effect of interfacial-active elements addition on the incorporation of micron-sized SiC particles in molten pure aluminum. Ceram Int. 2014;40(6):8323.

Valibeygloo N, Khosroshahi RA, Mousavian RT. Microstructural and mechanical properties of Al-4.5 wt% Cu reinforced with alumina nanoparticles by stir casting method. Int J Miner Metall Mater. 2013;20(10):978.

Roshan M, Mousavian TR, Ebrahimkhani H, Mosleh A. Fabrication of Al-based composites reinforced with Al2O3–Tib2 ceramic composite particulates using vortex-casting method. J Min Metall Sect B. 2013;49(3):299.

Khosroshahi NB, Khosroshahi RA, Mousavian RT, Brabazon D. Effect of electroless coating parameters and ceramic particle size on fabrication of a uniform Ni–P coating on SiC particles. Ceram Int. 2014;40(8):12149.

Khosroshahi NB, Khosroshahi RA, Mousavian RT, Brabazon D. Electroless deposition (ED) of copper coating on micron-sized SiC particles. Surf Eng. 2014;30(10):747.

Noori H, Mousavian RT, Khosroshahi RA, Brabazon D, Damadi SR. Effect of SiC particle morphology on Co–P electroless coating characteristics. Surf Eng. 2015. doi:10.1179/1743294415Y.0000000035.

Mohammadpour M, Khosroshahi RA, Mousavian RT, Brabazon D. A novel method for incorporation of micron-sized SiC particles into molten pure aluminum utilizing a Co coating. Metall Mater Trans B. 2015;46(1):12.

Raju KSR, Raju VR, Raju PRM, Ghosal P. Launching particle to constant reinforcement ratio as a parameter for improving the nanoreinforcement distribution and tensile strength of aluminum nanometal matrix composites. In: Proceedings of International Conference on Advances in Design and Manufacturing. Tiruchirappalli, 2015.1.

Raju KSR, Raju VR, Raju PRM, Ghosal P. Investigation of novel parameters affecting distribution of reinforcement in nano metal matrix composites. Int J Nanomanuf. 2015;11(1–2):94.

Boostani AF, Tahamtan S, Jiang ZY, Wei D, Yazdani S, Khosroshahi RA, Mousavian RT, Xu J, Zhang X, Gong D. Enhanced tensile properties of aluminium matrix composites reinforced with graphene encapsulated SiC nanoparticles. Compos A. 2015;68(2):155.

Su H, Gao WL, Zhang H, Liu HB, Lu J, Lu Z. Study on preparation of large sized nanoparticle reinforced aluminium matrix composite by solid-liquid mixed casting process. Mater Sci Technol. 2012;28(2):178.

Xu J, Chen L, Choi H, Li X. Theoretical study and pathways for nanoparticle capture during solidification of metal melt. J Phys Condens Matter. 2012;24(25):255304.

Xu J, Chen L, Choi H, Konish H, Li X. Assembly of metals and nanoparticles into novel nanocomposite superstructures. Sci Rep. 2013;3:1.

Xanthopoulou G, Marinou A, Vekinis G, Lekatou A, Vardavoulias M. Ni–Al and NiO–Al composite coatings by combustion-assisted flame spraying. Coatings. 2014;4(2):231.

Lee J-M, Kang S-B, Sato T, Tezuka H, Kamio A. Evolution of iron aluminide in Al/Fe in situ composites fabricated by plasma synthesis method. Mater Sci Eng A. 2003;362(1):257.

Rajan T, Pillai R, Pai B. Functionally graded Al–Al3Ni in situ intermetallic composites: fabrication and microstructural characterization. J Alloys Compd. 2008;453(1):L4.

Rajan T, Pillai R, Pai B. Characterization of centrifugal cast functionally graded aluminum–silicon carbide metal matrix composites. Mater Charact. 2010;61(10):923.

Rams J, Urena A, Escalera M, Sánchez M. Electroless nickel coated short carbon fibres in aluminium matrix composites. Compos A Appl Sci Manuf. 2007;38(2):566.

Farkoosh A, Pekguleryuz M. The effects of manganese on the Τ-phase and creep resistance in Al–Si–Cu–Mg–Ni alloys. Mater Sci Eng A. 2013;582:248.

Lee J-M, Kang S-B, Sato T, Tezuka H, Kamio A. Fabrication of Al/Al3Fe composites by plasma synthesis method. Mater Sci Eng A. 2003;343(1):199.

Goulart PR, Lazarine VB, Leal CV, Spinelli JE, Cheung N, Garcia A. Investigation of intermetallics in hypoeutectic Al–Fe alloys by dissolution of the Al matrix. Intermetallics. 2009;17(9):753.

Blundell D, Wai S. Measurement of van der Waal’s forces between iron/iron surfaces in water by atomic force microscopy. Microsc Microanal. 2005;11(S2):382.

Acknowledgments

This work was financially supported by the Iran National Science Foundation (No. 91002190).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mousavian, R.T., Khosroshahi, R.A., Yazdani, S. et al. Manufacturing of cast A356 matrix composite reinforced with nano- to micrometer-sized SiC particles. Rare Met. 36, 46–54 (2017). https://doi.org/10.1007/s12598-015-0689-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-015-0689-9