Abstract

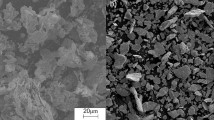

Nanocomposites of aluminum matrix reinforced with nanomaterials made using conventional casting techniques usually contain an incomplete dispersion of nanoparticles in the matrix. Recently, the use of aluminum powders for the entrance of nanoparticles into the melt by semi-solid particulate-injection casting has been examined to improve the dispersion of nanoparticles. In this study, A356–1 wt% SiC and A356–1 wt% Al2O3 nanocomposites were produced using this mentioned method and the results were compared with the nanocomposites reinforced with the same amount of SiC and Al2O3 nanoparticles but without the addition of aluminum powders. The experimental results indicated that even without having any pre-treatment on the as-received nanoceramics, they will be dispersed to some extent in the matrix owing to semi-solid shear stress introduced via the rotation of the stirrer. However, it was found that the ball milling process with aluminum powders was effective for increasing the number of isolated nanopowders dispersed in the matrix, although some large clusters of nanopowders were detected that counteracted the otherwise potentially useful effects of the increased dispersion of single nanoparticles.

Similar content being viewed by others

References

Pramanik A, Littlefair G (2013) Fabrication of nano-particle reinforced metal matrix composites, in Advanced Materials Research, pp. 289–294

Khosroshahi NB, Mousavian RT, Khosroshahi RA, Brabazon D (2015) Mechanical properties of rolled A356 based composites reinforced by Cu-coated bimodal ceramic particles. Mater Des 83:678–688

Reddy PS, Kesavan R, Ramnath BV (2018) Investigation of mechanical properties of aluminium 6061-silicon carbide, boron carbide metal matrix composite. Silicon 10:495–502

Jayakumar T, Annamalai K (2018) Investigation of hot tensile behavior of silicon carbide and magnesium oxide reinforced aluminum matrix composites. Silicon:1–11

Anbuchezhiyan G, Mohan B, Sathianarayanan D, Muthuramalingam T (2017) Synthesis and characterization of hollow glass microspheres reinforced magnesium alloy matrix syntactic foam. J Alloys Compd 719:125–132

Anbuchezhiyan G, Muthuramalingam T, Mohan B (2018) Effect of process parameters on mechanical properties of hollow glass microsphere reinforced magnesium alloy syntactic foams under vacuum die casting. Arch Civ Mech Eng 18:1645–1650, 2018/09/01/ 2018

Chen D, Sixta M, Zhang X, De Jonghe L, Ritchie R (2000) Role of the grain-boundary phase on the elevated-temperature strength, toughness, fatigue and creep resistance of silicon carbide sintered with Al, B and C. Acta Mater 48:4599–4608

Fenghong C, Chang C, Zhenyu W, Muthuramalingam T, Anbuchezhiyan G (2019) Effects of silicon carbide and tungsten carbide in Aluminium metal matrix composites. Silicon:1–8

El-Mahallawi I, Shash Y, Eigenfeld K, Mahmoud T, Ragaie R, Shash A et al (2010) Influence of nanodispersions on strength–ductility properties of semisolid cast A356 Al alloy. Mater Sci Technol 26:1226–1231

Vijayabhaskar S, Rajmohan T (2018) Experimental investigation and optimization of machining parameters in WEDM of Nano-SiC particles reinforced magnesium matrix composites. Silicon:1–16

Utriga Filho S, Rodriguez R, Eartman J, Lavernia E (2003) Powder metallurgy-metal matrix composites-synthesis of diamond reinforced Al-Mg nano crystalline composite powder using ball milling, in Mater Sci. Forum, pp. 213–218

Yaghobizadeh O, Baharvandi HR, Ahmadi AR, Aghaei E (2018) Development of the properties of Al/SiC Nano-composite fabricated by stir cast method by means of coating SiC particles with Al. Silicon:1–7

Groza JR (1999) Sintering of nanocrystalline powders. Int J Powder Metall 35:59–66

Mussert K, Vellinga W, Bakker A, Van Der Zwaag S (2002) A nano-indentation study on the mechanical behaviour of the matrix material in an AA6061-Al2O3 MMC. J Mater Sci 37:789–794

Yu H (2010) Processing routes for aluminum based nano-composites. Worcester Polytechnic Institute

Vinod B, Ramanathan S, Ananthi V, Selvakumar N (2018) Fabrication and characterization of organic and in-organic reinforced A356 aluminium matrix hybrid composite by improved double-stir casting. Silicon:1–13

Boostani AF, Mousavian RT, Tahamtan S, Yazdani S, Khosroshahi RA, Wei D et al (2016) Solvothermal-assisted graphene encapsulation of SiC nanoparticles: a new horizon toward toughening aluminium matrix nanocomposites. Mater Sci Eng A 653:99–107

Mousavian RT, Khosroshahi RA, Yazdani S, Brabazon D (2017) Manufacturing of cast A356 matrix composite reinforced with nano-to micrometer-sized SiC particles. Rare Metals 36:46–54

Shabani MO, Heydari F, Khorram A (2018) The effect of electromagnetic stirrer on the size and morphology of intermetallic particles in Al-Si metal matrix composite. Silicon:1–8

De Cicco M, Konishi H, Cao G, Choi HS, Turng L-S, Perepezko JH et al (2009) Strong, ductile magnesium-zinc nanocomposites. Metall Mater Trans A 40:3038–3045

Cao G, Choi H, Konishi H, Kou S, Lakes R, Li X (2008) Mg–6Zn/1.5% SiC nanocomposites fabricated by ultrasonic cavitation-based solidification processing. J Mater Sci 43:5521–5526

Li X, Yang Y, Cheng X (2004) Ultrasonic-assisted fabrication of metal matrix nanocomposites. J Mater Sci 39:3211–3212

Ezatpour H, Sajjadi SA (2011) Microstructure and mechanical properties of Al/Al2O3 micro and nano nanocomposites fabricated by a novel stirr casting, in 2th conferences on applications of nano technologie in sciences, engineering and Medicines-NTC 2011

Lan J, Li X (2004) Magnesium matrix Nano-composite fabricated by ultrasonic dispersion of Nano-sized SiC particles in molten magnesium alloy, in ASME 2004 international mechanical engineering congress and exposition, pp. 411–414

Kheirifard R, Beigi Khosroshahi N, Azari Khosroshahi R, Taherzadeh Mousavian R, Brabazon D (2016) Fabrication of A356-based rolled composites reinforced by Ni–P-coated bimodal ceramic particles. Proceedings of the Institution of Mechanical Engineers, Part L: Journal of Materials: Design and Applications, p. 1464420716649631

Mousavian RT, Damadi S, Khosroshahi RA, Brabazon D, Mohammadpour M (2015) A comparison study of applying metallic coating on SiC particles for manufacturing of cast aluminum matrix composites. Int J Adv Manuf Technol 81:433–444

Soltani S, Khosroshahi RA, Mousavian RT, Jiang Z-Y, Boostani AF, Brabazon D (2017) Stir casting process for manufacture of Al–SiC composites. Rare Metals 36:581–590

Boostani AF, Yazdani S, Mousavian RT, Tahamtan S, Khosroshahi RA, Wei D et al (2015) Strengthening mechanisms of graphene sheets in aluminium matrix nanocomposites. Mater Des 88:983–989

Boostani AF, Mousavian RT, Tahamtan S, Yazdani S, Khosroshahi RA, Wei D, Xu JZ, Gong D, Zhang XM, Jiang ZY (2015) Graphene sheets encapsulating SiC nanoparticles: a roadmap towards enhancing tensile ductility of metal matrix composites. Mater Sci Eng A 648:92–103

Rasidhar L, Krishna AR, Rao CS (2013) Fabrication and investigation on properties of ilmenite (FeTiO3) based Al-nanocomposite by stir casting process. J BioSci Biotechnol 5

Ezatpour HR, Sajjadi SA, Sabzevar MH, Huang Y (2014) Investigation of microstructure and mechanical properties of Al6061-nanocomposite fabricated by stir casting. Mater Des 55:921–928, 3//

Su H, Gao WL, Zhang H, Liu HB, Lu J, Lu Z (2012) Study on preparation of large sized nanoparticle reinforced aluminium matrix composite by solid–liquid mixed casting process. Mater Sci Technol 28:178–183

Tahamtan S, Halvaee A, Emamy M, Zabihi M (2013) Fabrication of Al/A206–Al2O3 nano/micro composite by combining ball milling and stir casting technology. Mater Des 49:347–359

Zhang L-J, Qiu F, Wang J-G, Jiang Q-C (2015) High strength and good ductility at elevated temperature of nano-SiCp/Al2014 composites fabricated by semi-solid stir casting combined with hot extrusion. Mater Sci Eng A 626:338–341 2015/02 2015

Dehghan Hamedan A, Shahmiri M (2012) Production of A356–1wt% SiC nanocomposite by the modified stir casting method. Mater Sci Eng A 556:921–926 2012/10 2012

Mazahery A, Abdizadeh H, Baharvandi H (2009) Development of high-performance A356/nano-Al 2 O 3 composites. Mater Sci Eng A 518:61–64

Sreekumar V, Pillai R, Pai B, Chakraborty M (2008) A study on the formation of MgAl2O4 and MgO crystals in Al–Mg/quartz composite by differential thermal analysis. J Alloys Compd 461:501–508

Brabazon D, Browne D, Carr A (2002) Mechanical stir casting of aluminium alloys from the mushy state: process, microstructure and mechanical properties. Mater Sci Eng A 326:370–381

Akbari MK, Mirzaee O, Baharvandi H (2013) Fabrication and study on mechanical properties and fracture behavior of nanometric Al 2 O 3 particle-reinforced A356 composites focusing on the parameters of vortex method. Mater Des 46:199–205

Akbari MK, Baharvandi H, Mirzaee O (2013) Nano-sized aluminum oxide reinforced commercial casting A356 alloy matrix: evaluation of hardness, wear resistance and compressive strength focusing on particle distribution in aluminum matrix. Compos Part B 52:262–268

Amirkhanlou S, Niroumand B (2011) Development of Al356/SiC p cast composites by injection of SiC p containing composite powders. Mater Des 32:1895–1902

Amirkhanlou S, Niroumand B (2012) Fabrication and characterization of Al356/SiC p semisolid composites by injecting SiC p containing composite powders. J Mater Process Technol 212:841–847

Munz D, Fett T (2013) Ceramics: mechanical properties, failure behaviour, materials selection, vol 36. Springer Science & Business Media

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Behnamfard, S., Mousavian, R.T., Afkham, Y. et al. Dry Milling of Aluminum and Ceramic Nanoparticles for a Particulate-Injection Casting of Aluminum Matrix Nanocomposites. Silicon 12, 913–920 (2020). https://doi.org/10.1007/s12633-019-00183-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-019-00183-9