Abstract

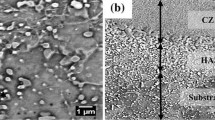

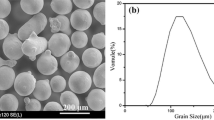

This paper presents a laser surface modification process of AISI H13 tool steel using 0.09, 0.2 and 0.4 mm size of laser spot with an aim to increase hardness properties. A Rofin DC-015 diffusion-cooled CO2 slab laser was used to process AISI H13 tool steel samples. Samples of 10 mm diameter were sectioned to 100 mm length in order to process a predefined circumferential area. The parameters selected for examination were laser peak power, overlap percentage and pulse repetition frequency (PRF). X-ray diffraction analysis (XRD) was conducted to measure crystallinity of the laser-modified surface. X-ray diffraction patterns of the samples were recorded using a Bruker D8 XRD system with Cu K α (λ=1.5405 Å) radiation. The diffraction patterns were recorded in the 2θ range of 20 to 80°. The hardness properties were tested at 981 mN force. The laser-modified surface exhibited reduced crystallinity compared to the un-processed samples. The presence of martensitic phase was detected in the samples processed using 0.4 mm spot size. Though there was reduced crystallinity, a high hardness was measured in the laser-modified surface. Hardness was increased more than 2.5 times compared to the as-received samples. These findings reveal the phase source of the hardening mechanism and grain composition in the laser-modified surface.

Similar content being viewed by others

References

F.O. Olsen, L. Alting, Manuf. Technol. 44, 141 (1995)

R.J. DiMelfi, P.G. Sanders, B. Hunter, Surf. Coat. Technol. 106, 30 (1998)

SeDao, M. Hua, T.M. Shao, H.Y. Tam, J. Mater. Process. Technol. 209, 4689 (2009)

R. Roy, S. Gedevanishvili, E. Breval, P. Mistry, M. Turchan, Mater. Lett. 46, 30 (2000)

F. Audebert, R. Colaço, R. Vilar, H. Sirkin, Scr. Mater. 48, 281 (2003)

M. Li, Y. Wang, B. Han, W. Zhao, T. Han, Appl. Surf. Sci. 255, 7574 (2009)

C. Cui, J. Hu, Y. Liu, K. Gao, Z. Guo, Appl. Surf. Sci. 254, 6779 (2008)

L. Yajiang, W. Juan, Z. Bing, F. Tao, Bull. Mater. Sci. 25, 213 (2002)

F. Wang, A. Shan, X. Dong, J. Wu, Scr. Mater. 56, 737 (2007)

T.A. Lograsso, A.R. Ross, D.L. Schlagel, A.E. Clark, M. Wun-Fogle, J. Alloys Compd. 350, 95 (2003)

S.N. Aqida, S. Naher, D. Brabazon, AIP Conf. Proc. 1353, 1081 (2011)

E. Yasar, H. Gungunes, S. Akturk, T.N. Durlu, J. Alloys Compd. 428, 125 (2007)

A.S.J. Suiker, S. Turteltaub, Philos. Mag. 87, 5033 (2007)

M. Brezenitsky, R. Moreh, D. Dayan, G. Kimmel, J. Alloys Compd. 290, 257 (1999)

M. Movaghar Garabagh, S. Hossein Nedjad, M. Nili Ahmadabadi, J. Mater. Sci. 43, 6840 (2008)

M. Eroglu, M. Aksoy, Mater. Sci. Eng. A, Struct. Mater.: Prop. Microstruct. Process. 286, 289 (2000)

Acknowledgements

The authors would like to acknowledge the support from the Ministry of Higher Education Malaysia, Universiti Malaysia Pahang and Dublin City University for funding this research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Aqida, S.N., Brabazon, D. & Naher, S. An investigation of phase transformation and crystallinity in laser surface modified H13 steel. Appl. Phys. A 110, 673–678 (2013). https://doi.org/10.1007/s00339-012-7149-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00339-012-7149-2